15 Oct What Causes Alternator to Fail?

If you’ve noticed your voltmeter dropping and your lights getting dim, there are a few things you want to check before replacing your alternator. Alternators fail from either overcharging or undercharging.

Some symptoms you may have for overcharging are: bright or burned out lights, batteries may smell, battery cases may be swollen, high voltmeter readings. Symptoms of undercharging are: slow or no cranking, dim lights, slow signals, dead batteries.

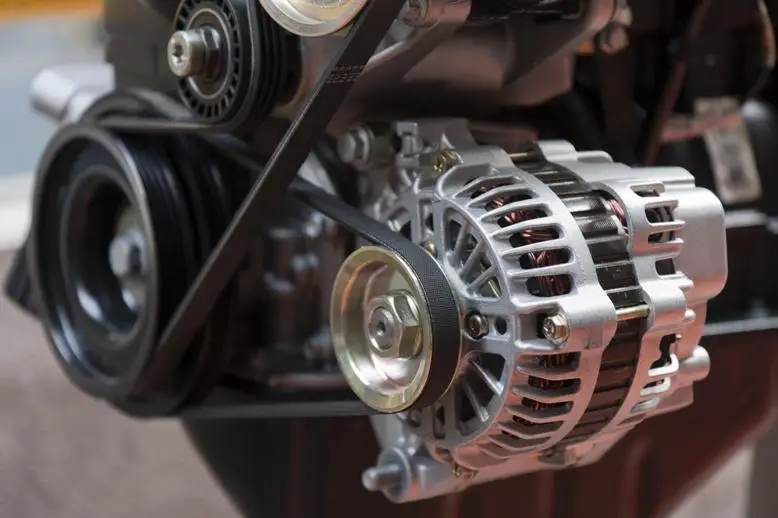

There are other factors to consider as well like the wires and cables that tie the system together, belts that make it go, and the age of the components.

The first thing I would check would be the condition of the batteries, they must be charged to 12 volts before load testing them, once that has been done use a heavy-duty load tester, on a 31 series battery with 950 CCA you should be able to pull 800 with a volt reading at 10.

If your voltage is lower or slow to recover try slow charging the battery a bit longer then retest. If you have no or a low reading replace the battery. When load testing, test each set of batteries by themselves, not together.

Once you have determined your battery source is solid, clean your battery cables before reinstalling them on the batteries. Next while your cables are still off, go inspect the cables on the alternator, are they tight? Now remove them, are the cables clean?

If you have a poor connection between the alternator and the starter and then to the batteries you will have dead batteries. So besides checking for clean connections you may want to test the cables as well.

Next check the belt tension on the alternator, if it’s loose it will slip and not charge, if it’s too tight it will put a strain on the alternator bearings. Now that everything has been inspected it’s time to test the output of the alternator. Check the voltage of the alternator with a voltmeter it should be 12-12.5V with the truck off, and running should be 13.5-14.2V Note: some ford systems may be as high as 15.5V but should not exceed that. Average should be at least 122 for a 135amp alt, replace the alternator if the output voltage exceeds 15.5V or if the current output is less than 90% of rating.

Some alternator tips to keep in mind, never use a pressure washer to clean the alternator. Watch the belt tension and check the mounting bolts on a regular basis. Watch how many accessories you add to your truck’s system, the bigger the load the shorter the alternator’s life span.

If you upgrade to a higher output alternator, you must also update your cables, the stock ones may char or burn from the higher loads. Check your batt and alt connections, they often come loose from the vibration of your motor.